Product Features

Table Data

Downloads

Recommended Products

-

CategoriesCable Cleats

-

Design SpecificationIEC 61914

-

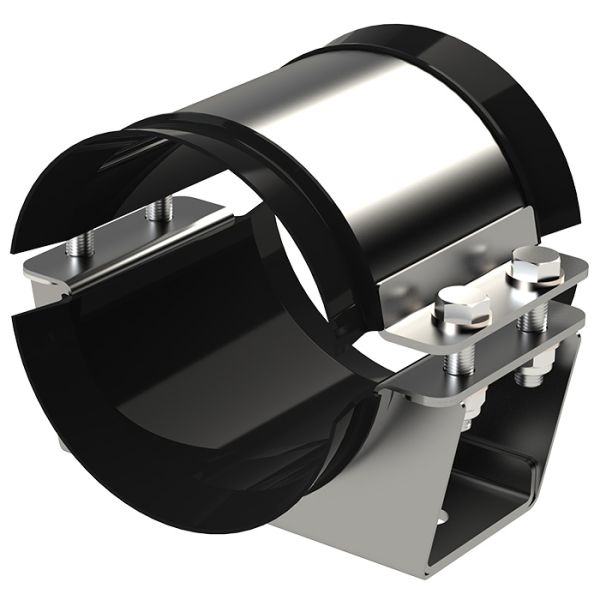

Cable TypeIEC 61914 6.1.3 Composite QHDSS - Quad Heavy Duty Stainless Steel

-

Material316L Stainless Steel

-

Needle Flame TestPass - 120 seconds IEC 61914 clause 10.0, 10.1, IEC 60695-11-5

-

Impact ResistancePass - Very heavy IEC 61914 clause 6.3, 6.3.5, 9.2

| CABLE CLEAT SELECTION TABLE | ||||||||||

| SHVSS-JSC PART NO. |

TYPE | CABLE Ø RANGE TAKE (mm) |

DIMENSIONS (mm) | WEIGHT (g) | ||||||

| W1 | W2* | H1 | H2 | D | P* | FIXING HOLE Ø | ||||

| * These dimensions can be adapted to suit specific applications | ||||||||||