Product Features

Table Data

Recommended Products

-

CategoriesCable Cleats

-

Design SpecificationIEC 61914

-

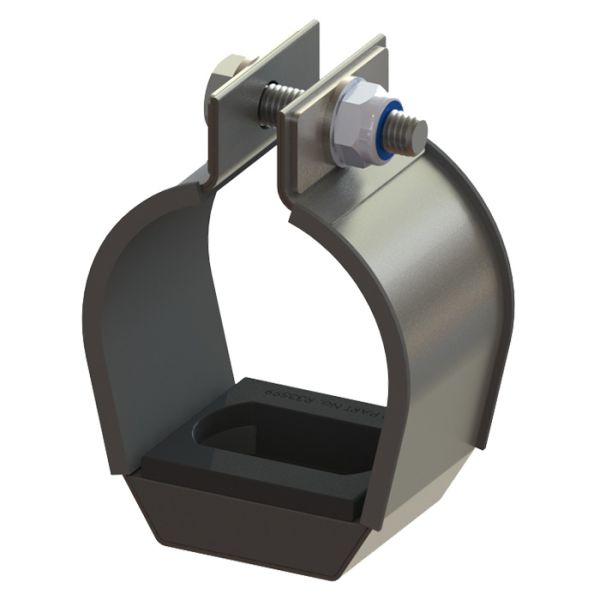

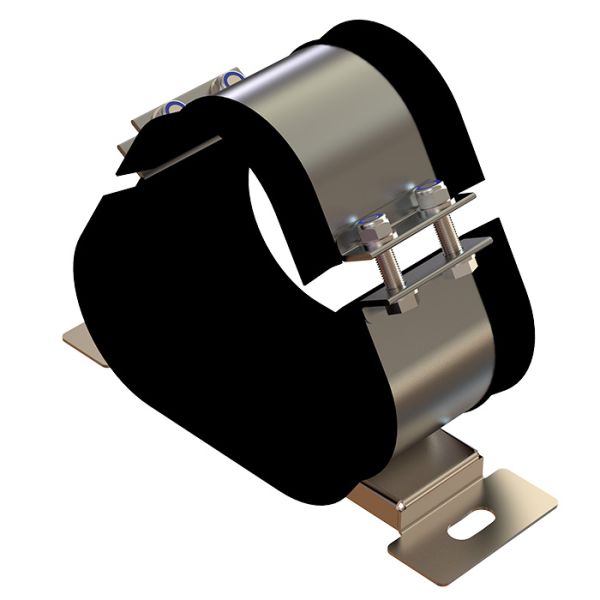

Cable TypeIEC 61914 6.1.3 Composite QHDSS - Quad Heavy Duty Stainless Steel

-

Material316L stainless steel with standard liners

-

Needle Flame TestPass - 120 second flame application time IEC 61914 clause 10.0, 10.1, IEC 60695-11-5

-

Impact ResistancePass - Very heavy

| QUAD PART NO. | CABLE Ø RANGE | DIMENSIONS (mm) | WEIGHT (g) | |||||

| W | H | D | P | FIXING HOLE Ø | ||||

| D1 | D2 | |||||||

| QHDSS015020 | 15- 20 | 66 | 89 | 58 | N/A | N/A | 1 x M10 | 430 |

| QHDSS019023 | 19-23 | 69 | 95 | 58 | N/A | N/A | 1 x M10 | 440 |

| QHDSS021027 | 21-27 | 76 | 103 | 58 | N/A | N/A | 1 x M10 | 513 |

| QHDSS026031 | 26-31 | 80 | 111 | 58 | N/A | N/A | 1 x M10 | 516 |

| QHDSS030034 | 30-34 | 83 | 117 | 58 | N/A | N/A | 1 x M10 | 524 |

| QHDSS031035 | 31-35 | 84 | 119 | 55 | 25 | 2 x M10 | 1 x M10 | 535 |

| QHDSS033037 | 33-37 | 87 | 122 | 55 | 25 | 2 x M10 | 1 x M10 | 537 |

| QHDSS036040 | 36-40 | 93 | 129 | 55 | 25 | 2 x M10 | 1 x M10 | 546 |

| QHDSS039043 | 39-43 | 99 | 135 | 55 | 25 | 2 x M10 | 1 x M10 | 553 |

| QHDSS041045 | 41-45 | 103 | 139 | 55 | 25 | 2 x M10 | 1 x M10 | 575 |

| QHDSS044047 | 44-47 | 107 | 142 | 55 | 25 | 2 x M10 | 1 x M10 | 562 |

| QHDSS046051 | 46-51 | 113 | 149 | 55 | 50 | 2 x M10 | 1 x M10 | 643 |

| QHDSS049053 | 49-53 | 119 | 155 | 55 | 50 | 2 x M10 | 1 x M10 | 649 |

| QHDSS052056 | 52-56 | 125 | 161 | 55 | 50 | 2 x M10 | 1 x M10 | 664 |

| QHDSS055059 | 55-59 | 131 | 167 | 55 | 50 | 2 x M10 | 1 x M10 | 667 |

| QHDSS058062 | 58-62 | 137 | 173 | 55 | 50 | 2 x M10 | 1 x M10 | 686 |

| QHDSS061065 | 61-65 | 143 | 179 | 55 | 50 | 2 x M10 | 1 x M10 | 703 |

| QHDSS064068 | 64-68 | 149 | 185 | 55 | 75 | 2 x M10 | 1 x M10 | 812 |

| QHDSS067071 | 67-71 | 155 | 191 | 55 | 75 | 2 x M10 | 1 x M10 | 830 |

CMP Thorus (SSCAL)

The THORUS cable support cleat has been designed, constructed and tested in accordance with...

CMP Emerald (SSDSS)

The Emerald cable cleats are metallic cable cleats which have been designed, constructed, and...

CMP Everest (HVSS-CC)

CMP Everest trefoil cable cleat range has been designed for the safe retention of high voltage...

CMP Helios (FPC)

The Helios Standard Duty, One Bolt, High Temperature Fire Rated Stainless Steel single cable...