Product Features

Table Data

Downloads

Recommended Products

-

CategoriesCable Cleats

-

Design SpecificationIEC 61914

-

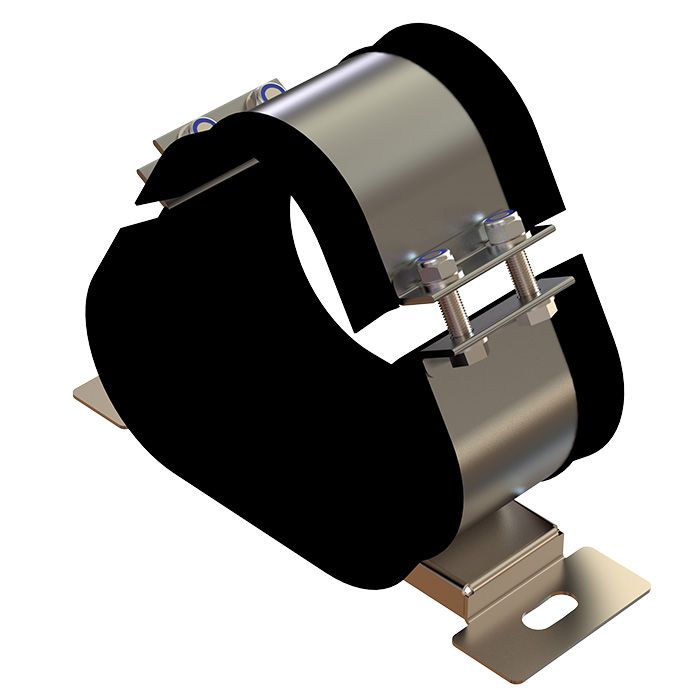

Cable TypeIEC 61914 6.1.3 Composite

-

Material316L Stainless Steel

-

Needle Flame TestPass - 120 seconds IEC 61914 clause 10.0, 10.1, IEC 60695-11-5

-

Impact ResistancePass - Very heavy IEC 61914 clause 6.3, 6.3.5, 9.2

| HVSS-CC Part No. |

Cable Ø RANGE TAKE (mm) |

DIMENSIONS mm | Weight (g) | ||||||

| W1 | W2 | H1 | H2 | D | P | D1 | |||

| HVSS-CC-100110-FX | 100-110 | 239 | 334 | 221 | 244 | 156 | 282 | 2 x M16 | 3019 |

| HVSS-CC-110120-FX | 110-120 | 259 | 354 | 239 | 262 | 156 | 302 | 2 x M16 | 3208 |

| HVSS-CC-120130-FX | 120-130 | 279 | 374 | 258 | 281 | 156 | 322 | 2 x M16 | 3396 |

| HVSS-CC-130140-FX | 130-140 | 299 | 394 | 277 | 300 | 156 | 342 | 2 x M16 | 3585 |

| HVSS-CC-140150-FX | 140-150 | 319 | 414 | 295 | 318 | 156 | 362 | 2 x M16 | 3774 |

| HVSS-CC-150160-FX | 150-160 | 339 | 434 | 314 | 337 | 156 | 382 | 2 x M16 | 3962 |

| HVSS-CC-160170-FX | 160-170 | 359 | 454 | 333 | 356 | 156 | 402 | 2 x M16 | 4151 |

| HVSS-CC-170180-FX | 170-180 | 379 | 474 | 351 | 374 | 156 | 422 | 2 x M16 | 4340 |

| HVSS-CC-180190-FX | 180-190 | 399 | 494 | 370 | 393 | 156 | 442 | 2 x M16 | 4528 |

| HVSS-CC-190200-FX | 190-200 | 419 | 514 | 389 | 412 | 156 | 462 | 2 x M16 | 4717 |