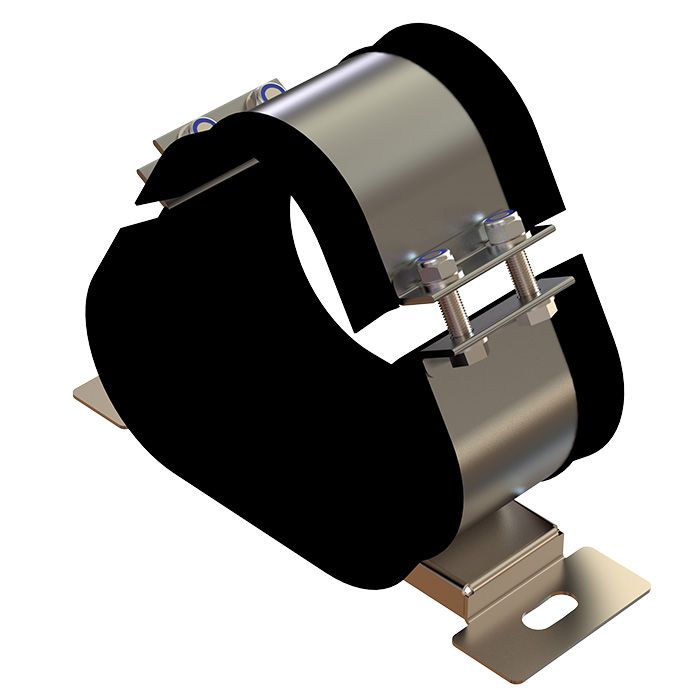

The Everest trefoil range of cable cleats are designed for use with high voltage cable installations and are manufactured to suit a range of cable diameters. The range consists of three cable cleats designed to be installed as a system; a fixed cleat, a slide cleat and an intermediate restraint or float cleat (if required).

The Everest fixed cleat is designed to secure the cables in a trefoil formation to a mounting surface, providing excellent axial and lateral retention. This variation securely holds the cables to a support structure. The Everest fixed cleat can be installed in a rigid system where there would be no allowance for movement within the system.

The Everest slide cleat is designed to secure cables in trefoil formation to a mounting surface, whilst providing excellent axial and lateral load retention the sliding base design allows for the cables to move in a horizontal direction, perpendicular to the cables direction. The Everest slide cleat is to be installed in a flexible system, where a snaking method is adopted. The slide bases allow the cables to expand the arc within the snake so to take up additional length generated by thermal expansion.

Everest Float Cleat is designed to secure cables in trefoil formation. The Everest float cleat would be installed between two fixed cleat or a fixed cleat and sliding cleat to be an intermediate restraint, allowing for greater fixed/sliding cleat spacing.

HVSS-CC cleats are fabricated in non-magnetic 316L stainless steel.

Flame retardant low smoke and fume fixed liners are fitted as standard, helping to:

- Restrain the cables within vertical applications.

- Provide a layer of protection to both the cable sheath and the cable cleat, during normal operation where thermal elongation of cable occurs.

- Protect the cable from chafing on any mounting surface due to differential movements, such as those found in marine and offshore applications.

- Assist in the extra protection of cables in the event of short circuit fault condition

Features

- Third party certification to IEC 61914

- Available in 316L stainless steel

- Sunlight (UV) resistant

- Operating temperature -60°C to +90°C

- Available in slide or fixed design

- Excellent axial and lateral load retention