Product Features

Table Data

Downloads

Recommended Products

-

CategoriesCable Cleats

-

Design SpecificationIEC 61914

-

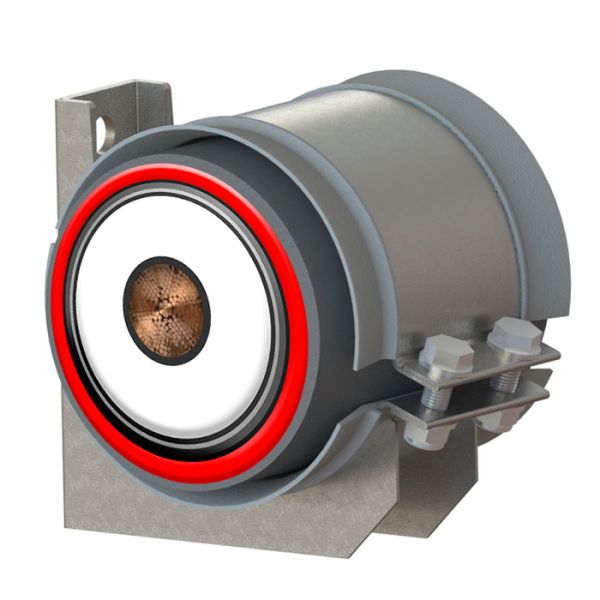

Cable Type6.1.3 Composite Strap Cable Cleat - 2 Loop Cyclone I

-

Material5000 Series Aluminium with Standard Liner Standard liners are classified as Low Smoke & Fume (LSF), Zero Halogen (LS0H) and Phosphorus Free

-

Needle Flame TestPass - 120 second flame application time IEC 61914 clause 10.0, 10.1, IEC 60695-11-5

-

Impact ResistanceVery Heavy IEC 61914 clause 6.3, 6.3.5, 9.2

| Cyclone I Part No. | Intermediate Restraint Part No. | Cable Ø Range Take (mm) | Dimensions (mm) | Weight (g) | |||||||

| Single | Trefoil | Quad | W | H | D | P | Fixing Hole Ø | ||||

| D1 | D2 | ||||||||||

| 1CYC024034 | 2STR024034 | 36-50 | 24-34 | 21-29 | 108 | 96 | 89 | 80 | 2 x M10 | 1 x M12 | 347 |

| 1CYC030041 | 2STR030041 | 45-60 | 30-41 | 26-35 | 108 | 109 | 89 | 80 | 2 x M10 | 1 x M12 | 358 |

| 1CYC037047 | 2STR037047 | 55-69 | 37-47 | 32-40 | 128 | 120 | 89 | 100 | 2 x M10 | 1 x M12 | 393 |

| 1CYC043054 | 2STR043054 | 64-80 | 43-54 | 37-46 | 128 | 134 | 89 | 100 | 2 x M10 | 1 x M12 | 406 |

| 1CYC050060 | 2STR050060 | 75-88 | 50-60 | 43-51 | 148 | 145 | 89 | 120 | 2 x M10 | 1 x M12 | 465 |

| 1CYC056067 | 2STR056067 | 83-99 | 56-67 | 49-57 | 148 | 158 | 89 | 120 | 2 x M10 | 1 x M12 | 478 |

| 1CYC063073 | 2STR063073 | 94-108 | 63-73 | 55-62 | 168 | 170 | 89 | 140 | 2 x M10 | 1 x M12 | 514 |

| 1CYC069080 | 2STR069080 | 103-118 | 69-80 | 60-68 | 168 | 183 | 89 | 140 | 2 x M10 | 1 x M12 | 527 |

| 1CYC072085 | 2STR072085 | 114-150 | 72-85 | 66-72 | 188 | 193 | 89 | 160 | 2 x M10 | 1 x M12 | 596 |

| 1CYC082095 | 2STR082095 | 145-165 | 82-95 | 70-81 | 188 | 212 | 89 | 160 | 2 x M10 | 1 x M12 | 615 |

| 1CYC092105 | 2STR092105 | 92-105 | 70-81 | 210 | 231 | 89 | 100 | 2 x M10 | 1 x M12 | 653 | |

| 1CYC102115 | 2STR102115 | 102-115 | 88-98 | 210 | 250 | 89 | 100 | 2 x M10 | 1 x M12 | 672 | |

| 1CYC112125 | 2STR112125 | 112-125 | 96-107 | 235 | 269 | 89 | 100 | 2 x M10 | 1 x M12 | 751 | |

| 1CYC122135 | 2STR122135 | 122-135 | 105-116 | 235 | 288 | 89 | 100 | 2 x M10 | 1 x M12 | 771 | |

| 1CYC132145 | 2STR132145 | 132-145 | 113-124 | 250 | 307 | 89 | 120 | 2 x M10 | 1 x M12 | 808 | |

Data Sheets

CMP Venus Quad Cable Cleat (QPSS)

The Venus Quad Cable Cleat (QPSS) are metallic cable cleats which have been designed,...

CMP Saturn Quad (QSDSS)

The Saturn quad cable cleats are metallic cable cleats which have been designed, constructed,...

CMP SHVSS-WM

CMP SHVSS-WM wall mounted single cable cleat is a composite cable cleat which has been...

CMP Sapphire (SHDSS)

The SHDSS cable cleat range consists of metallic cable cleats which have been designed,...