Product Features

Table Data

Recommended Products

-

CategoriesCable Cleats

-

Design SpecificationIEC 61914:2015

-

Cable Type6.1.3 Composite

-

MaterialStainless Steel

-

Needle Flame TestPass - 120 seconds IEC 61914 clause 10.0, 10.1, IEC 60695-11-5

-

Impact ResistancePass - Very heavy IEC 61914 clause 6.3, 6.3.5, 9.2

| TITAN Part No. | Cable ø range take (mm) | Length (mm) | Dimensions (mm) | Base Fixing | Weight (g) | |||||

| H | W | L | L2 | W2 | P | |||||

| SCSS-100110-400 | 100-110 | 400 | 287.8 | 298.4 | 400 | 90 | 170 | 120 | 2 x M16 | 7541 |

| SCSS-100110-600 | 100-110 | 600 | 287.8 | 298.4 | 600 | 90 | 170 | 120 | 2 x M16 | 9448 |

| SCSS-100110-800 | 100-110 | 800 | 287.8 | 298.4 | 800 | 90 | 170 | 120 | 2 x M16 | 11337 |

| SCSS-110120-400 | 110-120 | 400 | 306.4 | 318.5 | 400 | 90 | 180 | 120 | 2 x M16 | 8560 |

| SCSS-110120-600 | 110-120 | 600 | 306.4 | 318.5 | 600 | 90 | 180 | 120 | 2 x M16 | 10693 |

| SCSS-110120-800 | 110-120 | 800 | 306.4 | 318.5 | 800 | 90 | 180 | 120 | 2 x M16 | 12704 |

| SCSS-120130-400 | 120-130 | 400 | 325.1 | 338.7 | 400 | 90 | 190 | 120 | 2 x M16 | 8404 |

| SCSS-120130-600 | 120-130 | 600 | 325.1 | 338.7 | 600 | 90 | 190 | 120 | 2 x M16 | 10560 |

| SCSS-120130-800 | 120-130 | 800 | 325.1 | 338.7 | 800 | 90 | 19 | 120 | 2 x M16 | 12692 |

| SCSS-130140-400 | 130-140 | 400 | 343.7 | 358.8 | 400 | 90 | 200 | 120 | 2 x M16 | 8837 |

| SCSS-130140-600 | 130-140 | 600 | 343.7 | 358.8 | 600 | 90 | 200 | 120 | 2 x M16 | 11122 |

| SCSS-130140-800 | 130-140 | 800 | 343.7 | 358.8 | 800 | 90 | 200 | 120 | 2 x M16 | 13125 |

| SCSS-140150-400 | 140-150 | 400 | 362.4 | 379 | 400 | 90 | 210 | 140 | 2 x M16 | 9268 |

| SCSS-140150-600 | 140-150 | 600 | 362.4 | 379 | 600 | 90 | 210 | 140 | 2 x M16 | 12101 |

| SCSS-140150-800 | 140-150 | 800 | 362.4 | 379 | 800 | 90 | 210 | 140 | 2 x M16 | 13934 |

| SCSS-150160-400 | 150-160 | 400 | 381.1 | 399.1 | 400 | 90 | 220 | 140 | 2 x M16 | 9702 |

| SCSS-150160-600 | 150-160 | 600 | 381.1 | 399.1 | 600 | 90 | 220 | 140 | 2 x M16 | 12238 |

| SCSS-150160-800 | 150-160 | 800 | 381.1 | 399.1 | 800 | 90 | 220 | 140 | 2 x M16 | 14739 |

| SCSS-160170-400 | 160-170 | 400 | 399.7 | 419.3 | 400 | 90 | 230 | 140 | 2 x M16 | 10134 |

| SCSS-160170-600 | 160-170 | 600 | 399.7 | 419.3 | 600 | 90 | 230 | 140 | 2 x M16 | 12797 |

| SCSS-160170-800 | 160-170 | 800 | 399.7 | 419.3 | 800 | 90 | 230 | 140 | 2 x M16 | 15281 |

| SCSS-170180-400 | 170-180 | 400 | 418.4 | 439.4 | 400 | 90 | 240 | 160 | 2 x M16 | 10568 |

| SCSS-170180-600 | 170-180 | 600 | 418.4 | 439.4 | 600 | 90 | 240 | 160 | 2 x M16 | 13354 |

| SCSS-170180-800 | 170-180 | 800 | 418.4 | 439.4 | 800 | 90 | 240 | 160 | 2 x M16 | 15961 |

| SCSS-180190-400 | 180-190 | 400 | 437 | 459.6 | 400 | 90 | 250 | 160 | 2 x M16 | 11002 |

| SCSS-180190-600 | 180-190 | 600 | 437 | 459.6 | 600 | 90 | 250 | 160 | 2 x M16 | 13917 |

| SCSS-180190-800 | 180-190 | 800 | 437 | 459.6 | 800 | 90 | 250 | 160 | 2 x M16 | 16640 |

| SCSS-190200-400 | 190-200 | 400 | 455.7 | 479.8 | 400 | 90 | 260 | 160 | 2 x M16 | 11444 |

| SCSS-190200-600 | 190-200 | 600 | 455.7 | 479.8 | 600 | 90 | 260 | 160 | 2 x M16 | 14478 |

| SCSS-190200-800 | 190-200 | 800 | 455.7 | 479.8 | 800 | 90 | 260 | 160 | 2 x M16 | 17494 |

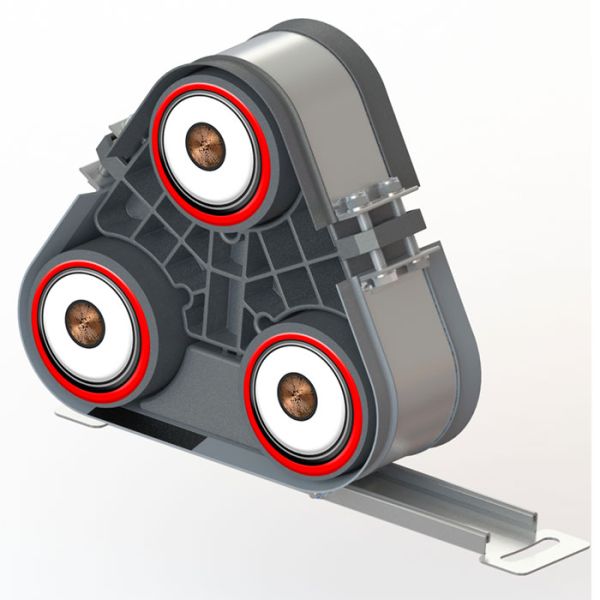

CMP Sphinx (SCAL)

The SPHINX cable support cleat has been designed, constructed and tested in accordance with...

CMP HVSS-EC

CMP HVSS-EC trefoil cable cleat is a composite cable cleat which has been designed,...

CMP Sovereign (HDSS)

The Sovereign cable cleats are metallic cable cleats which have been designed, constructed,...