Product Features

Table Data

Downloads

Recommended Products

-

CategoriesCable Glands

-

Design SpecificationBS 6121:Part 1:1989, IEC 62444, EN 62444

-

Mechanical Classification*Impact = Level 8, Cable Anchorage = Type D

-

Ingress Protection Rating **IP66, IP67 and IP68***

-

Cable TypeLead Sheathed & Single Wire Armour (LC/SWA), Lead Sheathed & Aluminium Wire Armour (LC/AWA), Lead Sheathed & Wire Braid Armour (LC/SWB), Lead Sheathed & Pliable Wire Armour (LC/PWA), Lead Sheathed & Steel Tape Armour (LC/STA), Lead Sheathed & Aluminium Strip Armour (LC/ASA)

-

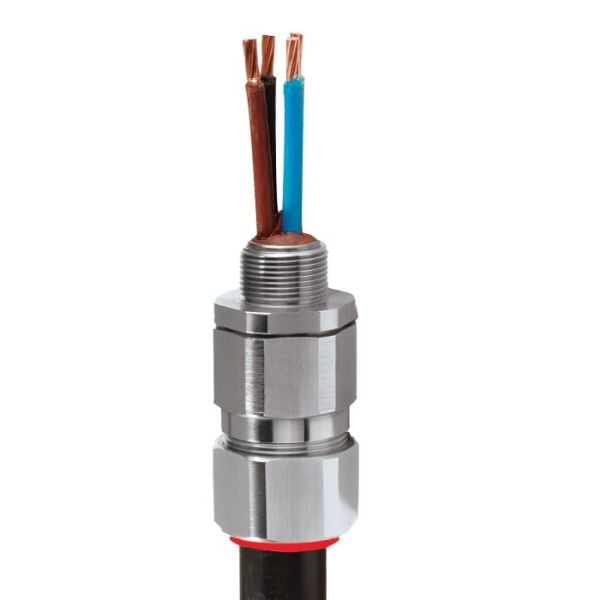

MaterialStainless Steel

-

Seal MaterialCMP SOLO LSF Halogen Free Thermoset Elastomer / Epoxy Barrier Compound

-

Armour ClampingReversible Armour Cone and AnyWay Universal Clamping Ring

-

Sealing Area(s)Cable Inner Bedding and Outer Cable Sheath

|

Cable Gland Size |

Available Entry Threads 'C' |

Lead Sheath Diameter 'A' |

Overall Cable Diameter 'B' |

Armour Range | Across Flats 'D' |

Across Corners 'D' |

Combined Ordering Reference |

Shroud | Cable Gland Weight (Kgs) |

|||||||||||

| Standard | Option |

Grooved Cone (X) |

Stepped Cone (W) |

|||||||||||||||||

| Metric |

Thread Length (Metric) 'E' |

NPT |

Thread Length (NPT) 'E' |

NPT | Min | Max | Min | Max | Min | Max | Min | Max | Max | Max | Size | Type | Ordering Suffix |

|||

| 20S16 | M20 | 15.0 | ½' | 19.9 | ¾' | 3.1 | 7.8 | 6.1 | 13.1 | 0.3 | 1.0 | 0.8 | 1.25 | 24.0 | 26.4 | 20S16 | TE1FUPB | 1RA4 | PVC04 | 0.15 |

| 20S | M20 | 15.0 | ½' | 19.9 | ¾' | 6.1 | 11.0 | 9.5 | 15.9 | 0.3 | 1.0 | 0.8 | 1.25 | 24.0 | 26.4 | 20S | TE1FUPB | 1RA4 | PVC04 | 0.15 |

| 20 | M20 | 15.0 | ½' | 19.9 | ¾' | 6.5 | 13.4 | 12.5 | 20.9 | 0.4 | 1.0 | 0.8 | 1.25 | 30.5 | 33.6 | 20 | TE1FUPB | 1RA4 | PVC06 | 0.23 |

| 25S | M25 | 15.0 | ¾' | 20.2 | 1' | 11.1 | 19.3 | 14.0 | 22.0 | 0.4 | 1.2 | 1.25 | 1.6 | 37.5 | 41.3 | 25S | TE1FUPB | 1RA4 | PVC09 | 0.35 |

| 25 | M25 | 15.0 | ¾' | 20.2 | 1' | 11.1 | 19.3 | 18.2 | 26.2 | 0.4 | 1.2 | 1.25 | 1.6 | 37.5 | 41.3 | 25 | TE1FUPB | 1RA4 | PVC09 | 0.35 |

| 32 | M32 | 15.0 | 1' | 25 | 1 ¼' | 17.0 | 25.5 | 23.7 | 33.9 | 0.4 | 1.2 | 1.6 | 2.0 | 46.0 | 50.6 | 32 | TE1FUPB | 1RA4 | PVC11 | 0.55 |

| 40 | M40 | 15.0 | 1 ¼' | 25.6 | 1 ½' | 22.0 | 31.2 | 27.9 | 40.4 | 0.4 | 1.6 | 1.6 | 2.0 | 55.0 | 60.5 | 40 | TE1FUPB | 1RA4 | PVC15 | 0.80 |

| 50S | M50 | 15.0 | 1 ½' | 26.1 | 2' | 29.5 | 37.2 | 35.2 | 46.7 | 0.4 | 1.6 | 2.0 | 2.5 | 60.0 | 66.0 | 50S | TE1FUPB | 1RA4 | PVC18 | 1.01 |

| 50 | M50 | 15.0 | 2' | 26.9 | 2 ½' | 35.6 | 42.6 | 40.4 | 53.0 | 0.6 | 1.6 | 2.0 | 2.5 | 70.1 | 77.1 | 50 | TE1FUPB | 1RA4 | PVC21 | 1.38 |

| 63S | M63 | 15.0 | 2' | 26.9 | 2 ½' | 40.1 | 48.5 | 45.6 | 59.4 | 0.6 | 1.6 | 2.0 | 2.5 | 75.0 | 82.4 | 63S | TE1FUPB | 1RA4 | PVC23 | 1.51 |

| 63 | M63 | 15.0 | 2 ½' | 39.9 | 3' | 47.2 | 54.2 | 54.6 | 65.8 | 0.6 | 1.6 | 2.0 | 2.5 | 80.0 | 88.0 | 63 | TE1FUPB | 1RA4 | PVC25 | 1.57 |

| 75S | M75 | 15.0 | 2 ½' | 39.9 | 3' | 52.8 | 60.2 | 59.0 | 72.0 | 0.6 | 1.6 | 2.0 | 2.5 | 90.0 | 99.0 | 75S | TE1FUPB | 1RA4 | PVC28 | 2.46 |

| 75 | M75 | 15.0 | 3' | 41.5 | 3 ½' | 59.1 | 65.2 | 66.7 | 78.4 | 0.6 | 1.6 | 2.5 | 3.0 | 100.0 | 110.0 | 75 | TE1FUPB | 1RA4 | PVC30 | 3.15 |

| 90 | M90 | 24.0 | 3 ½' | 42.8 | 4' | 66.6 | 77.1 | 76.2 | 90.3 | 0.8 | 1.6 | 3.15 | 4.0 | 115.0 | 126.5 | 90 | TE1FUPB | 1RA4 | PVC32 | 4.63 |

| 100 | M100 | 24.0 | 4' | 44.0 | 5' | 76.0 | 88.1 | 86.1 | 101.4 | 0.8 | 1.6 | 3.15 | 4.0 | 127.0 | 139.7 | 100 | TE1FUPB | 1RA4 | LSF33 | 4.97 |

| 115 | M115 | 24.0 | 4' | 44.0 | 5' | 86.0 | 94.1 | 101.5 | 110.2 | 0.8 | 1.6 | 3.15 | 4.0 | 138.0 | 151.8 | 115 | TE1FUPB | 1RA4 | LSF34 | 7.60 |

| 130 | M130 | 24.0 | 5' | 46.8 | 6' | 97.0 | 110.1 | 110.2 | 123.2 | 0.8 | 1.6 | 3.15 | 4.0 | 157.0 | 172.7 | 130 | TE1FUPB | 1RA4 | LSF35 | 8.77 |

| Dimensions displayed in millimeters unless otherwise stated | ||||||||||||||||||||

Data Sheets

CMP TE1FU | Explosive Atmosphere Cable Gland

• Stainless steel compact design

• Fully sequential, three step installation...

CMP PX2KPB | Explosive Atmosphere Barrier Cable Gland

• Effectively earths / grounds lead sheathed cables

• Metal-to-metal armour...

CMP Triton CDS | Explosive Atmosphere Cable Gland

• Fully sequential, three step installation procedure, reduces installation times, cost...

CMP PX2K | Explosive Atmosphere Cable Gland

• Metal-to-metal armour clamping

• Direct & remote installation, compound...