Product Features

Table Data

Downloads

Recommended Products

-

CategoriesCable Glands

-

Design SpecificationBS 6121:Part 1:1989, IEC 62444, EN 62444

-

Mechanical Classification*Impact = Level 8, Cable Anchorage = Type D

-

Ingress Protection Rating **NEMA 4X & IP66

-

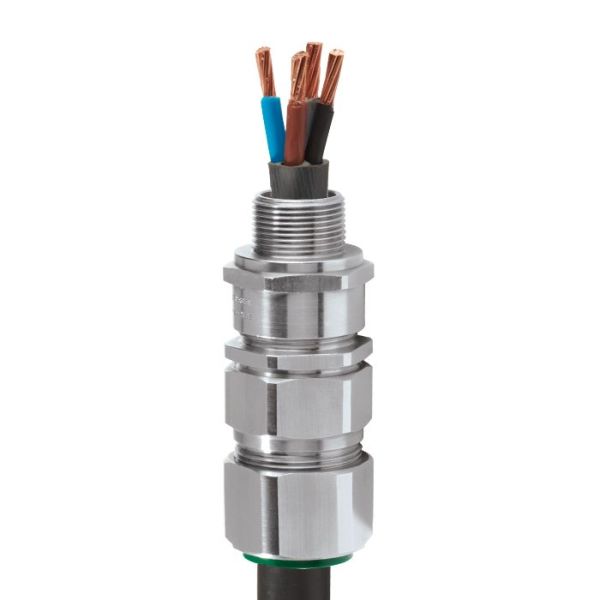

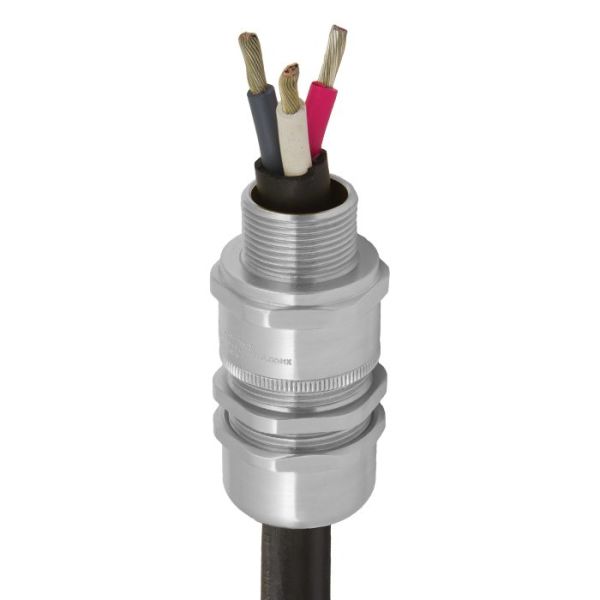

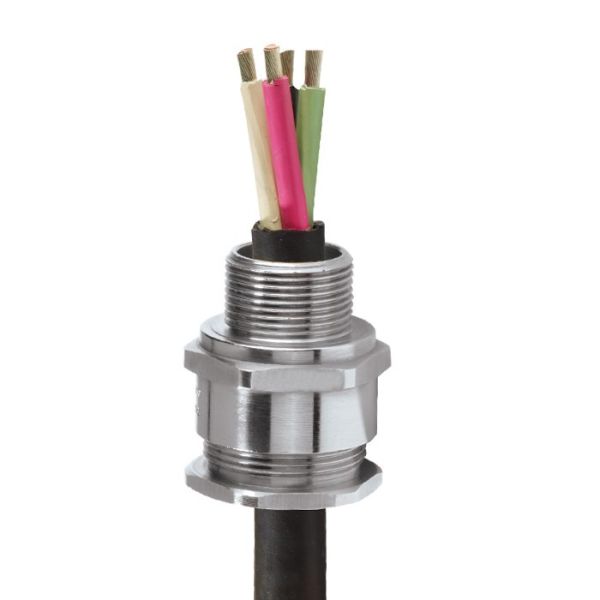

Cable TypeCorrugated & Interlocked Metal Clad Armour (MC) or TECK90, Continuously Welded Metal Clad Armour (MCHL), ACIC-HL, ACWU90-HL, RC90-HL, RA90-HL

-

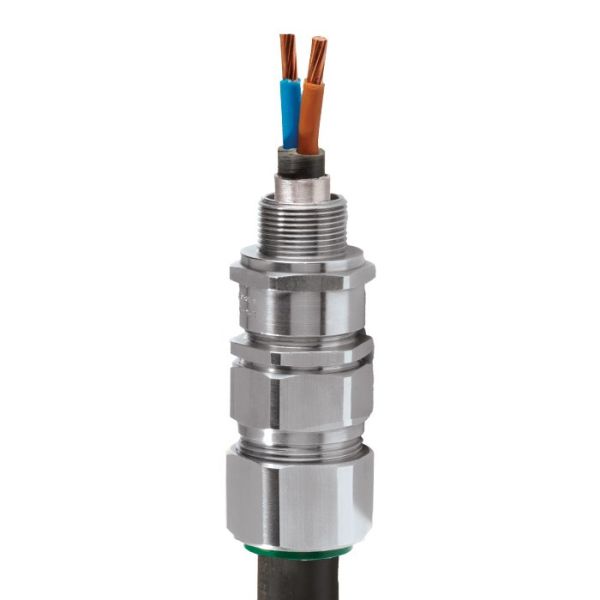

MaterialCopper Free Aluminium (<0.4%), Electroless Nickel Plated Brass, Stainless Steel

-

Seal MaterialCMP SOLO LSF Halogen Free Thermoset Elastomer

-

Armour Clamping360° Stainless Steel Grounding Spring (non-magnetic)

-

Sealing Area(s)Cable Outer Jacket

|

Order Reference (NPT) |

Entry Thread 'C' |

Minimum Thread Length 'E' |

Minimum Thread Length 'E' |

Cable Armor Diameter 'A' |

Cable Jacket Diameter 'B' |

Nominal Assembly Length 'F' |

Max | Shroud | Weight (Kgs) |

||||||||

|

End Stop In |

End Stop Out |

||||||||||||||||

| Aluminum |

Nickel Plated Brass |

Stainless Steel |

NPT | Metric | NPT | Metric | Min | Max | Min | Max | Min | Max |

Across Flats 'D' |

Across Corners 'D' |

|||

| TMC050SA | TMC050SNB | TMC050SSS | ½' | M20 | 19.8 | 15.0 | No Stop | No Stop | 8.6 | 12.7 | 8.9 | 14.0 | 46.5 | 30.5 | 33.5 | PVC06 | 0.22 |

| TMC050A | TMC050NB | TMC050SS | ½' | M20 | 19.8 | 15.0 | No Stop | No Stop | 13.0 | 17.0 | 11.2 | 20.1 | 52.3 | 36.1 | 39.6 | PVC09 | 0.28 |

| TMC075A | TMC075NB | TMC075SS | ¾' | M25 | 20.3 | 15.0 | 15.0 | 19.3 | 19.3 | 23.4 | 17.0 | 26.4 | 53.1 | 40.9 | 45.2 | PVC10 | 0.33 |

| TMC100A | TMC100NB | TMC100SS | 1' | M32 | 24.9 | 15.0 | 19.8 | 24.6 | 24.6 | 29.2 | 22.1 | 32.3 | 56.9 | 50.0 | 55.1 | PVC13 | 0.50 |

| TMC125A | TMC125NB | TMC125SS | 1 ¼' | M40 | 25.7 | 15.0 | 27.4 | 31.2 | 31.2 | 35.3 | 29.5 | 38.1 | 56.4 | 55.1 | 60.5 | PVC15 | 0.59 |

| TMC150A | TMC150NB | TMC150SS | 1 ½' | M50 | 26.2 | 15.0 | 33.5 | 37.1 | 37.1 | 41.1 | 35.6 | 44.2 | 58.7 | 59.9 | 66.0 | PVC18 | 0.69 |

| TMC200SA | TMC200SNB | TMC200SSS | 2' | M50 | 26.9 | 15.0 | 38.4 | 42.7 | 42.7 | 47.0 | 40.1 | 50.0 | 64.0 | 70.1 | 77.0 | PVC21 | 1.20 |

| TMC200A | TMC200NB | TMC200SS | 2' | M63 | 26.9 | 15.0 | 45.0 | 49.0 | 49.0 | 53.1 | 47.2 | 56.1 | 63.2 | 74.9 | 82.6 | PVC23 | 1.10 |

| TMC250SA | TMC250SNB | TMC250SSS | 2 ½' | M75 | 39.9 | 15.0 | 52.1 | 54.9 | 54.9 | 58.9 | 52.8 | 62.0 | 69.3 | 80.0 | 88.1 | PVC25 | 1.70 |

| TMC250A | TMC250NB | TMC250SS | 2 ½' | M75 | 39.9 | 15.0 | 57.2 | 61.2 | 61.2 | 64.8 | 59.2 | 68.1 | 72.1 | 85.1 | 93.5 | PVC27 | 1.60 |

| TMC300A | TMC300NB | TMC300SS | 3' | M90 | 41.4 | 15.0 | 64.5 | 70.6 | 70.6 | 75.4 | 66.5 | 79.5 | 98.3 | 110.0 | 120.9 | LSF32 | 3.50 |

| TMC350A | TMC350NB | TMC350SS | 3½' | M100 | 42.9 | 24.1 | 73.9 | 83.6 | 83.6 | 88.6 | 75.9 | 97.3 | 117.6 | 133.4 | 146.8 | LSF34 | 6.70 |

| TMC400A | TMC400NB | TMC400SS | 4' | M115 | 43.9 | 24.1 | 73.9 | 83.6 | 83.6 | 88.6 | 75.9 | 97.3 | 117.6 | 133.4 | 146.8 | LSF34 | 7.50 |

Data Sheets

CMP E2FW | Explosive Atmosphere Cable Gland

• Effectively earths / grounds lead sheathed cables

• Metal-to-metal armour...

CMP E1FW | Explosive Atmosphere Cable Gland

• Metal-to-metal armour clamping, direct & remote installation

...

CMP SS2K | Explosive Atmosphere Cable Gland

• Provides double seal on outer sheath or single on outer & inner, direct &...

CMP A2F | Explosive Atmosphere Cable Gland

• Displacement type seal

• Deluge protected

• -60°C to...